Introduction

As a leading shock absorber manufacturing facility with decades of automotive suspension expertise and comprehensive vehicle dynamics analysis, we encounter countless cases of vehicle vibration and shaking issues daily. Through our extensive research, field testing, and collaboration with automotive technicians worldwide, we’ve identified the primary causes of car shaking while driving and their relationship to suspension system components.

Car shaking while driving represents one of the most common automotive complaints affecting vehicle safety, comfort, and component longevity. Our manufacturing experience and diagnostic data reveal that while multiple factors can cause vehicle vibration, certain root causes appear consistently across different vehicle types, driving conditions, and maintenance histories.

Understanding the most common cause of car shaking enables vehicle owners and automotive professionals to implement targeted diagnostic approaches, prioritize maintenance schedules, and select appropriate repair strategies. Our comprehensive analysis of vibration-related warranty claims and field failure reports provides authoritative insights into this widespread automotive concern.

Through systematic analysis of thousands of shaking-related complaints and our extensive manufacturing quality control data, we’ve determined that tire and wheel-related issues represent the overwhelming majority of car shaking cases, though suspension component deterioration also contributes significantly to vehicle vibration problems across all automotive segments.

The Most Common Cause: Tire and Wheel Issues

Wheel Imbalance – The Primary Culprit

Our comprehensive field data analysis reveals that wheel imbalance represents the single most common cause of car shaking while driving, accounting for approximately 60-70% of all vibration-related complaints received by automotive service facilities worldwide.

Wheel imbalance occurs when tire and wheel assembly weight distribution becomes uneven, creating centrifugal forces during rotation that translate into noticeable vehicle vibration. This condition typically develops gradually through normal tire wear, weight loss from wheel weights, or rapid onset from impact damage or improper tire installation.

The characteristic signature of wheel imbalance includes vibration intensity that increases with vehicle speed, typically becoming noticeable around 45-50 mph and intensifying significantly at highway speeds. Our engineering analysis shows that even minor weight variations of 0.25 ounces can create perceptible vibration at typical driving speeds.

Speed-Related Vibration Patterns Wheel imbalance creates predictable vibration patterns directly correlating with vehicle speed and wheel rotation frequency. At lower speeds (under 40 mph), wheel imbalance typically produces minimal noticeable vibration as centrifugal forces remain relatively low. However, as speed increases, the rotational forces multiply exponentially, creating increasingly severe vibration that can become uncomfortable or potentially dangerous at highway speeds.

Professional wheel balancing equipment measures static and dynamic imbalance with precision accuracy, identifying specific weight correction requirements for each wheel position. Our manufacturing specifications recommend routine wheel balancing every 10,000-15,000 miles or whenever tires are removed for service or replacement.

Dynamic vs. Static Imbalance Effects Static wheel imbalance creates vertical vibration as heavy spots cause the wheel to bounce during rotation, while dynamic imbalance produces side-to-side wobbling motion affecting steering stability and tire wear patterns.

Our technical analysis shows that most real-world wheel imbalance conditions involve both static and dynamic components requiring sophisticated balancing equipment for complete correction. Dynamic imbalance particularly affects steering wheel shake and requires precise weight placement at specific rim locations to counteract rotational forces.

Tire-Related Vibration Causes

Irregular Tire Wear Patterns Uneven tire wear represents the second most common tire-related cause of car shaking, creating vibration through inconsistent road contact and rotational imbalance. Our field analysis indicates that irregular wear patterns develop from alignment problems, suspension wear, or improper tire pressure maintenance.

Cupping wear patterns create particularly severe vibration as the tire develops high and low spots around the circumference, causing rhythmic impact with road surfaces. Our diagnostic procedures include comprehensive tire wear pattern analysis correlating specific wear characteristics with underlying mechanical problems.

Tire Construction Defects and Separation Manufacturing defects including belt separation, sidewall bulges, or internal structural failure create severe vibration that typically manifests as speed-independent shaking or rhythmic pulsation during driving.

Belt separation produces characteristic symptoms including visible tire deformation and rhythmic vibration regardless of speed. Internal tire separation requires immediate replacement as continued operation presents safety hazards including potential blowout or complete tread separation.

Tire Pressure Effects Improper tire pressure significantly affects vibration characteristics through altered contact patch geometry and increased rolling resistance. Our engineering data shows that even 5 psi pressure variations can create noticeable vibration changes, particularly at highway speeds.

Underinflated tires create excessive sidewall flexing leading to irregular wear patterns and increased vibration, while overinflation reduces contact patch size creating harsh ride characteristics. Regular pressure monitoring prevents these conditions while optimizing tire performance and longevity.

Secondary Common Causes of Car Shaking

Suspension System Component Wear

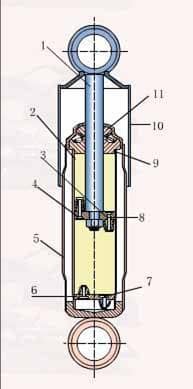

As shock absorber manufacturing specialists, we’ve identified that worn suspension components represent the second most common category of car shaking causes, though typically producing different vibration characteristics than tire and wheel issues.

Shock Absorber and Strut Deterioration Worn shock absorbers and struts create car shaking through loss of dampening control allowing excessive suspension oscillation and wheel hop during driving. Unlike wheel imbalance vibration, suspension-related shaking typically manifests during specific driving conditions rather than consistent speed-related patterns.

Our manufacturing analysis shows that shock absorber wear develops gradually, initially reducing ride quality before progressing to noticeable vibration and shaking. The characteristic signature includes increased vibration over rough roads, bouncing after speed bumps, and nose-diving during braking.

Ball Joint and Control Arm Wear Worn ball joints and control arms create car shaking through excessive play in suspension geometry allowing uncontrolled wheel movement during driving. This condition typically produces vibration that varies with steering input and road surface conditions.

Ball joint wear progresses from initial play development through complete failure, creating increasingly severe vibration and potential safety hazards. Control arm bushing deterioration allows excessive movement creating vibration during acceleration, braking, or turning maneuvers.

Drivetrain and Engine-Related Causes

CV Joint and Driveshaft Issues Worn constant velocity (CV) joints create car shaking particularly during turning maneuvers as damaged joints bind or skip during rotation. This condition typically produces clicking sounds accompanied by vibration, distinguishing it from tire or suspension-related causes.

Driveshaft imbalance or wear creates vibration similar to wheel imbalance though typically affecting the entire vehicle rather than specific areas. Professional diagnosis differentiates between driveshaft and wheel-related vibration through systematic component isolation testing.

Engine Mount Deterioration Worn engine mounts create car shaking through excessive engine movement during acceleration or idle operation. This vibration typically correlates with engine rpm rather than vehicle speed, providing diagnostic differentiation from wheel or suspension causes.

Brake System Vibration

Warped Brake Rotors Warped or damaged brake rotors create car shaking specifically during braking operations as brake pad contact with uneven rotor surfaces produces pulsation transmitted through the steering wheel or brake pedal.

Rotor warping typically results from excessive heat during heavy braking, improper installation, or manufacturing defects creating thickness variations. The characteristic signature includes vibration only during braking and steering wheel pulsation.

Diagnostic Approaches and Professional Analysis

Systematic Vibration Diagnosis

Speed Correlation Testing Professional vibration diagnosis begins with systematic speed correlation testing identifying whether car shaking increases, decreases, or remains constant with vehicle speed changes. This fundamental analysis differentiates between rotating component issues and other vibration sources.

Wheel and tire imbalance creates vibration that intensifies with speed, while suspension problems typically manifest during specific road conditions regardless of speed. Engine or transmission issues often correlate with rpm rather than vehicle speed.

Component Isolation Procedures Advanced diagnostic techniques include systematic component isolation identifying specific vibration sources through methodical elimination of potential causes. Professional technicians employ specialized equipment including vibration analyzers and electronic diagnostic tools.

Road Test Analysis Comprehensive road testing under various conditions enables correlation between driving scenarios and car shaking characteristics. Professional evaluation includes different speed ranges, road surfaces, steering inputs, and braking conditions isolating specific vibration triggers.

Professional Equipment and Measurement

Vibration Analysis Technology Modern diagnostic facilities employ sophisticated vibration analysis equipment measuring frequency, amplitude, and directional characteristics of car shaking problems. This technology enables precise identification of vibration sources and appropriate correction strategies.

Frequency analysis differentiates between tire/wheel vibration (typically 20-30 Hz at highway speeds), engine vibration (10-100 Hz depending on rpm), and suspension resonance (2-15 Hz).

Computer Wheel Balancing Professional computer wheel balancing equipment provides precision measurement and correction of both static and dynamic imbalance conditions. This technology exceeds manual balancing accuracy while ensuring complete vibration elimination across all speed ranges.

Prevention and Maintenance Strategies

Routine Maintenance Protocols

Tire and Wheel Care Regular tire rotation, pressure monitoring, and wheel balancing represent the most effective prevention strategies for the most common cause of car shaking. Our recommendations include 5,000-mile rotation intervals and annual wheel balancing service.

Proper tire pressure maintenance prevents uneven wear patterns while optimizing performance and fuel economy. Monthly pressure checks and seasonal adjustments account for temperature variations affecting tire pressure throughout the year.

Visual inspection identifies developing problems including irregular wear patterns, sidewall damage, or tread separation before they create severe vibration or safety hazards.

Suspension System Maintenance Regular suspension inspection and maintenance significantly reduces car shaking related to component wear. Our manufacturing recommendations include annual shock absorber evaluation and replacement intervals based on mileage and operating conditions.

Quality Component Selection

Premium Replacement Parts Selecting quality replacement components significantly affects long-term performance and vibration prevention. Our manufacturing standards exceed OEM requirements providing superior durability and performance characteristics compared to economy alternatives.

Quality shock absorbers, struts, and suspension components include advanced materials, precision manufacturing, and comprehensive testing ensuring optimal performance and longevity.

Professional Installation Standards Proper installation procedures significantly affect component performance and vibration characteristics. Our technical specifications define torque requirements, alignment procedures, and quality verification ensuring optimal results and warranty protection.

Conclusion

Through our comprehensive analysis of automotive vibration issues and extensive manufacturing experience, we’ve definitively identified that tire and wheel imbalance represents the most common cause of car shaking while driving, accounting for the majority of vibration-related complaints across all vehicle segments and operating conditions.

Wheel imbalance creates speed-dependent vibration that intensifies at highway speeds, distinguishing it from other vibration sources including suspension wear, drivetrain problems, or brake system issues. Professional wheel balancing provides effective correction while regular maintenance prevents recurrence and optimizes tire performance.

Secondary causes including suspension component wear, tire problems, and drivetrain issues contribute to car shaking but typically produce different vibration characteristics enabling systematic diagnostic differentiation. Prevention strategies including regular tire rotation, pressure monitoring, wheel balancing, and suspension maintenance significantly reduce car shaking incidents.

As automotive suspension manufacturing experts, we emphasize that addressing car shaking problems promptly prevents safety hazards, reduces repair costs, and maintains optimal vehicle performance throughout extended service life. Professional diagnosis and quality repair solutions provide effective vibration elimination and restored driving comfort.