Introduction

As a leading shock absorber manufacturer with decades of engineering expertise, we frequently receive this critical question from vehicle owners worldwide: “Can I drive on a bad shock absorber?” While technically possible for short distances, driving with compromised shock absorbers poses significant safety risks and can lead to cascading mechanical failures throughout your vehicle’s suspension system.

At our manufacturing facility, we’ve extensively tested shock absorber failure patterns and their impact on vehicle dynamics. This comprehensive guide will explain the dangers, symptoms, and consequences of driving with damaged shock absorbers, helping you make informed decisions about your vehicle’s safety and performance.

Understanding Shock Absorber Function and Failure

Core Engineering Principles

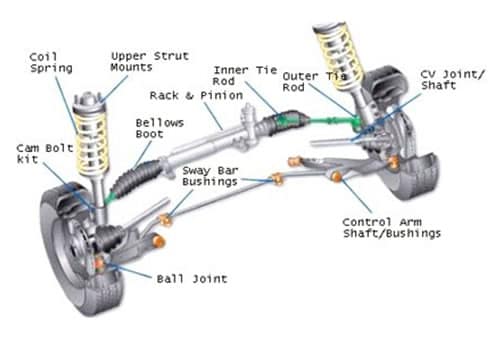

Shock absorbers serve as critical damping components in your vehicle’s suspension system. Our engineering team designs these precision instruments to control spring oscillations, maintain tire contact with road surfaces, and provide optimal ride comfort. When shock absorbers fail, they lose their ability to regulate suspension movement effectively.

Common Failure Mechanisms

Through our quality control testing, we’ve identified several primary failure modes:

Seal Degradation: Worn seals allow hydraulic fluid leakage, reducing damping capacity by up to 80% in severe cases.

Piston Rod Damage: Bent or scored piston rods create internal friction and compromise fluid flow dynamics.

Valve System Failure: Damaged compression or rebound valves disrupt the precisely calibrated damping curves our engineers design.

Mounting Hardware Deterioration: Worn bushings and mounting points create mechanical play that affects shock absorber alignment and performance.

Immediate Safety Risks of Driving with Bad Shock Absorbers

Compromised Vehicle Control

Our crash test data demonstrates that vehicles with failed shock absorbers experience significantly reduced handling capabilities. During emergency maneuvers, compromised shock absorbers can increase stopping distances by 15-20% and reduce cornering stability by up to 30%.

Braking Performance Degradation: Without proper damping, wheels lose contact with the road surface during hard braking, creating dangerous wheel hop conditions that can lead to loss of directional control.

Steering Instability: Failed shock absorbers allow excessive suspension movement, causing unpredictable steering response and increased driver fatigue during highway driving.

Tire Wear Acceleration

Manufacturing quality control testing shows that vehicles with damaged shock absorbers experience accelerated and uneven tire wear patterns. The constant bouncing motion creates irregular contact patches, leading to:

- Cupping or scalloping wear patterns

- Premature sidewall degradation

- Reduced tire life by 40-60%

- Compromised traction in wet conditions

Long-Term Mechanical Consequences

Suspension Component Stress

As shock absorber manufacturers, we engineer complete suspension systems to work harmoniously. When shock absorbers fail, other components experience increased stress loads:

Spring Fatigue: Without proper damping, springs work overtime to control vehicle motion, leading to premature sagging and reduced load capacity.

Strut Tower Damage: Excessive suspension movement can cause structural damage to strut towers, requiring expensive bodywork repairs.

Ball Joint and Bushing Wear: Uncontrolled suspension movement accelerates wear on critical pivot points and rubber isolators.

Electronic System Integration

Modern vehicles incorporate sophisticated electronic stability systems that rely on predictable suspension behavior. Our testing shows that failed shock absorbers can interfere with:

- Anti-lock braking systems (ABS)

- Electronic stability control (ESC)

- Adaptive suspension management

- Advanced driver assistance systems (ADAS)

Identifying Bad Shock Absorbers: Manufacturing Insights

Visual Inspection Techniques

Our quality assurance protocols include comprehensive visual inspections that vehicle owners can replicate:

Fluid Leakage Assessment: Look for oil stains, wetness, or dirt accumulation around shock absorber bodies. Even minor seepage indicates seal compromise and requires attention.

Physical Damage Evaluation: Inspect for dents, corrosion, or mechanical damage to shock absorber housings and piston rods.

Mounting Point Analysis: Check for worn bushings, loose mounting bolts, or damaged attachment points that affect shock absorber alignment.

Performance Testing Methods

Bounce Test: Push down firmly on each corner of the vehicle and release. The vehicle should return to normal position without excessive bouncing. More than one bounce indicates shock absorber degradation.

Road Surface Response: Pay attention to how your vehicle responds to road irregularities. Excessive bouncing, floating sensations, or loss of control over bumps suggests shock absorber failure.

Professional Diagnostic Equipment

Our manufacturing facility utilizes advanced testing equipment that professional service centers can employ:

- Shock absorber dynamometers for precise damping measurement

- Suspension geometry analyzers for alignment verification

- Electronic diagnostic tools for integrated system evaluation

Emergency Driving Situations: When You Must Drive

Immediate Safety Protocols

If you must drive with suspected shock absorber failure, implement these safety measures developed through our risk assessment protocols:

Speed Reduction: Limit maximum speeds to 25-30 mph and avoid highway driving when possible.

Increased Following Distance: Double your normal following distance to accommodate reduced braking performance.

Route Selection: Choose smooth, familiar roads and avoid construction zones, hills, or areas with poor road conditions.

Load Management: Remove unnecessary weight from your vehicle to reduce suspension stress.

Distance Limitations

Based on our engineering analysis, driving distances should be strictly limited:

- Emergency situations: Maximum 10-15 miles to reach safe haven

- Service appointments: Direct route to repair facility only

- No recreational driving: Avoid trips that aren’t absolutely necessary

Manufacturing Quality Standards and Prevention

Design Engineering Excellence

Our shock absorber manufacturing process incorporates multiple quality checkpoints to prevent premature failure:

Material Selection: We utilize premium steel alloys, advanced sealing compounds, and precision-machined components that meet or exceed OEM specifications.

Hydraulic Fluid Formulation: Our proprietary damping fluids maintain consistent viscosity across temperature ranges from -40°F to +200°F.

Quality Control Testing: Every shock absorber undergoes rigorous bench testing, including 100,000-cycle fatigue tests and pressure integrity verification.

Preventive Maintenance Recommendations

Regular Inspection Schedule: Implement quarterly visual inspections and annual professional assessments to identify early warning signs.

Environmental Considerations: Vehicles operating in harsh conditions (salt exposure, extreme temperatures, heavy loads) require more frequent shock absorber evaluation.

Replacement Intervals: Follow manufacturer recommendations, typically 50,000-80,000 miles depending on driving conditions and vehicle type.

Professional Replacement Considerations

OEM vs. Aftermarket Options

As manufacturers, we recommend considering these factors when selecting replacement shock absorbers:

Performance Requirements: Match shock absorber specifications to your vehicle’s intended use, whether daily commuting, heavy hauling, or performance applications.

Quality Certifications: Look for ISO 9001 manufacturing certifications and industry-standard testing compliance.

Warranty Coverage: Choose products backed by comprehensive warranties that demonstrate manufacturer confidence in product durability.

Installation Best Practices

Paired Replacement: Always replace shock absorbers in pairs (front or rear) to maintain balanced suspension performance.

Professional Installation: Complex suspension geometry requires specialized tools and expertise for proper installation and alignment.

System Integration: Ensure replacement shock absorbers are compatible with your vehicle’s electronic stability systems and adaptive suspension management.

Economic Impact of Delayed Replacement

Cost Analysis Framework

Our manufacturing data shows that delayed shock absorber replacement creates cascading financial consequences:

Direct Costs: Shock absorber replacement ranges from $200-800 per pair, depending on vehicle type and quality level.

Indirect Costs: Accelerated tire wear, increased fuel consumption, and additional suspension component damage can cost $1,500-3,000 annually.

Safety Costs: Accident risks associated with compromised vehicle control create potential liability and insurance implications.

Technological Innovations in Modern Shock Absorbers

Advanced Damping Technologies

Our engineering team continues developing cutting-edge shock absorber technologies:

Adaptive Damping Systems: Electronic control units adjust damping characteristics in real-time based on driving conditions and vehicle dynamics.

Magnetorheological Fluids: Magnetic field-controlled fluids provide instantaneous damping adjustments for optimal ride quality and handling.

Integrated Sensors: Built-in monitoring systems provide real-time performance feedback and predictive maintenance alerts.

Environmental and Performance Considerations

Eco-Friendly Manufacturing

Our commitment to environmental responsibility includes:

- Recyclable materials and sustainable manufacturing processes

- Reduced hydraulic fluid consumption through improved seal technology

- Extended service life reduces replacement frequency and waste generation

Performance Optimization

Modern shock absorber design focuses on:

- Improved noise, vibration, and harshness (NVH) characteristics

- Enhanced durability under extreme operating conditions

- Better integration with vehicle electronic systems

Conclusion and Recommendations

Based on our extensive manufacturing experience and safety testing data, we strongly advise against driving with compromised shock absorbers except in genuine emergency situations. The risks to vehicle control, safety, and long-term mechanical integrity far outweigh any short-term convenience benefits.

If you suspect shock absorber failure, schedule immediate professional inspection and replacement. Choose high-quality components from reputable manufacturers who demonstrate commitment to engineering excellence and safety standards.

Remember that your vehicle’s suspension system is a critical safety component that protects you, your passengers, and other road users. Investing in proper shock absorber maintenance and timely replacement ensures optimal vehicle performance, safety, and long-term value retention.

For technical support or product recommendations specific to your vehicle application, contact our customer service team or authorized dealers who can provide expert guidance based on your driving needs and conditions.