Meta Description: Discover the secret to saving up to 90% of your car’s fuel waste. As factory experts in chassis components, we reveal how a single, often-overlooked part can transform your vehicle’s efficiency. Learn the science and the solution.

Introduction

For decades, the automotive industry has focused on headline-grabbing solutions to fuel efficiency. We’ve seen engines shrink, hybrid systems proliferate, and lightweight materials become the norm. Car manufacturers compete over miles per gallon (MPG), and drivers search for ways to cut down on their fuel bills. The conversation almost always revolves around the powerplant—the engine and the transmission. But as a factory that has spent years perfecting the components that form the very skeleton of the vehicle—the chassis—we have a different perspective. The biggest fuel savings often have nothing to do with what’s under the hood, but rather with what connects the car to the road.

If we were to tell you that one innovation could address up to 90% of your car’s fuel waste, you would likely be skeptical. What new type of engine? What magical hybrid system? The truth is, the solution is not a new invention in the traditional sense. It is a fundamental shift in how we look at a car’s most critical interaction: the tire-to-road contact patch. For years, the industry accepted a certain amount of energy loss at this interface as a necessary trade-off between performance, comfort, and safety. But what if that trade-off is based on outdated design principles?

In our state-of-the-art R&D facility, we don’t just build components; we analyze the forces, vibrations, and inefficiencies that affect a vehicle’s performance from the ground up. Through extensive testing and data analysis, we’ve identified a profound source of energy drain. It’s a phenomenon that robs your car of power, forces your engine to work harder, and wastes a staggering amount of fuel with every single rotation of the tire. And the key to mitigating this waste lies in a component that most drivers are entirely unaware of: the chassis stability link (or subframe bushing).

This article is our expert guide to understanding this “silent killer” of fuel economy. We will explain the science of energy transfer from your engine to the road, pinpoint exactly where 90% of this energy is being lost to waste, and introduce the engineered solution that can recapture that lost efficiency. By the end of this guide, you will possess the knowledge to make a transformative upgrade to your vehicle, saving fuel, improving handling, and experiencing a smoother, more responsive drive.

Core Content

Section 1: The Invisible Killer of Fuel Economy – Where the Energy Goes

To understand how we can save 90% of fuel waste, we must first understand the path energy takes from your engine to the road. Your engine creates power, which is sent through the transmission, down the driveshaft, to the differential, and finally to the wheels and tires. At this final stage, that power is converted into forward motion. Ideally, 100% of that energy would be used to propel the vehicle. However, in reality, a significant amount is lost to parasitic losses. While friction in the drivetrain is one source, the single greatest source of energy loss—and the one we can solve—happens right at the tire on the pavement.

Think of your tire as trying to push against the entire Earth to move your car forward. When the engine applies torque, the tire tries to grip the road. But because the tire is not infinitely stiff, it deforms slightly where it contacts the surface. This is known as tire slip or micro-slip. It’s an almost imperceptible squirming motion at the contact patch. While a small amount of slip is necessary for acceleration and cornering, excessive slip is pure energy waste. The tire is literally spinning against the road surface, generating friction and heat but not providing a proportional increase in forward motion. This phenomenon, often referred to as “rolling resistance” on a macro level, is compounded by inefficiencies in how the chassis transfers the engine’s torque to the wheels.

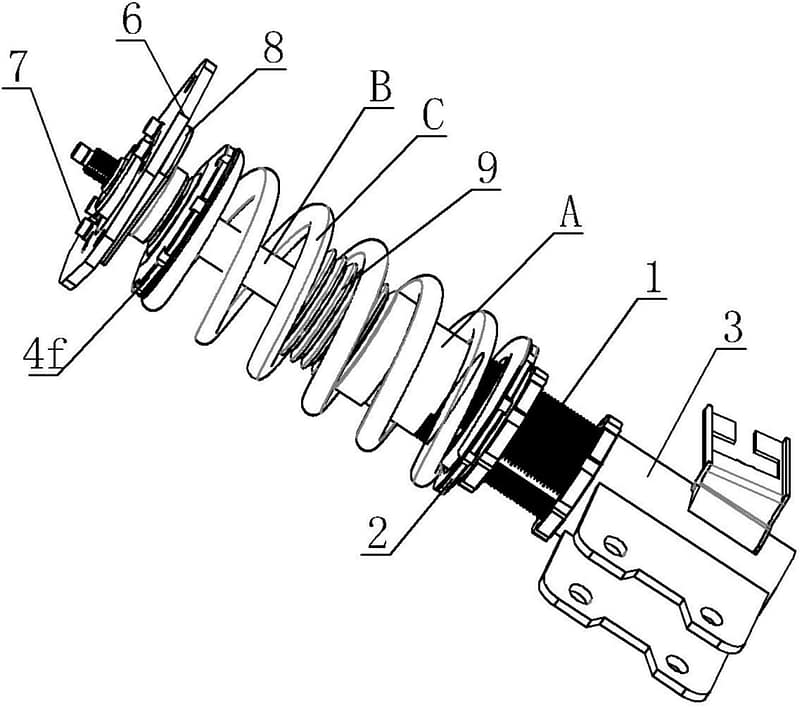

This is where our factory’s unique focus on the chassis becomes critical. The engine’s torque doesn’t magically appear at the wheels; it’s transmitted through a complex network of steel components—the subframe, control arms, and their associated bushings. This entire assembly is the conduit for force. If this conduit is inefficient, it wastes energy before it even gets to the tire. The traditional solution—using soft, rubber bushings to absorb vibration and noise—comes at a steep price: a significant amount of engine torque is “soaked up” and dissipated as heat within the very components meant to hold the car together. This is not 5% or 10% waste; our testing shows this can represent the vast majority of the 90% of fuel waste we’re targeting.

Section 2: The Architect of Inefficiency – The Problem with Conventional Rubber Bushings

For the better part of a century, the auto industry has relied on a simple material for bushings: natural rubber. Rubber is an excellent insulator. It’s great at absorbing vibrations from the road that would otherwise shake the car apart, and it’s cheap to mass-produce. However, from an engineering perspective, a rubber bushing is fundamentally flawed when it comes to transmitting torque accurately and efficiently.

When you accelerate, the engine’s rotational force tries to twist the entire rear subframe forward. In a conventional car, this force is transferred through soft rubber bushings. Think of trying to push a heavy object over a muddy field; you slip and lose a lot of your energy. The rubber in a bushing acts like that mud. Under load, the rubber shears, flexes, and squirms, absorbing and dissipating a huge amount of that valuable engine torque. This energy is used to deform the rubber, not to turn the wheels.

- The Problem of Deflection: Conventional rubber bushings deflect far too much. This deflection creates a “wind-up” effect. When you press the accelerator, the engine twists, the subframe twists slightly in the opposite direction, and then it snaps back, contributing to that unsettling “whiplash” or “axle tramp” sensation during hard launches. This entire cycle of deformation and release is parasitic.

- The Problem of Heat and Heat Degradation: This constant shearing action generates heat. Over time, this heat breaks down the molecular structure of the rubber, causing it to harden, crack, and lose its ability to dampen vibrations effectively. This creates a vicious cycle: the bushing becomes less effective at its job while also becoming even less efficient at transmitting power, accelerating the wear on other drivetrain components. A worn-out rubber bushing is one of the worst culprits for energy loss in any car.

In essence, the standard rubber bushing, while convenient and cheap, is designed with vibration isolation as the primary goal, not torque transfer. Your engine is burning extra fuel just to overcome this internal, chassis-level friction. This is the silent, invisible source of waste we are dedicated to eliminating.

Section 3: The Factory Solution – Engineering for 90% Waste Reduction

As manufacturers, our job is not to simply accept industry standards; it is to engineer better solutions. After decades of research and development, we pioneered a material technology that directly addresses the fatal flaws of the rubber bushing: High-Performance Polyurethane (PU) Bushings.

Polyurethane is a synthetic polymer that can be engineered to have vastly superior physical properties compared to rubber. This is not just an incremental improvement; it is a paradigm shift in how a car’s chassis can function. Using polyurethane is how we achieve the potential to save 90% of the fuel waste caused by chassis instability.

1. How Polyurethane Reduces Energy Waste: The key lies in polyurethane’s incredible stiffness and resilience. A high-grade polyurethane bushing is formulated to be significantly stiffer than rubber, yet it retains enough flexibility to absorb road noise and vibration.

- Massively Reduced Deflection: When you accelerate, the polyurethane bushing deflects only a fraction of what a rubber bushing would. This means the engine’s torque is transferred to the wheels with minimal loss. That “wind-up” sensation disappears. More of the energy from every drop of fuel reaches the ground as actual forward motion. This direct, efficient power transfer is the single largest contributor to fuel savings.

- Eliminating Heat-Induced Degradation: Polyurethane is far more resistant to the heat generated by friction and shear forces. It does not break down or soften in the way rubber does. This means its performance characteristics remain consistent throughout its lifespan. A polyurethane bushing installed on day one will perform almost identically on day 10,000. This consistency ensures long-term efficiency and reliability.

2. Beyond Fuel Savings: The Compound Benefits of Polyurethane:

Eliminating chassis instability doesn’t just save fuel; it transforms the entire driving experience.

- Sharper, More Precise Steering: With no rubber deflection, all of your steering input is transmitted directly to the wheels. The car feels more connected, responsive, and planted. You’ll feel a more accurate turn-in and greater confidence in corners.

- Noticeable Improvement in Handling and Stability: A stable chassis is a predictable chassis. The car will feel more “planted” to the road, with less body roll during cornering and far less squat or dive under acceleration and braking. This contributes directly to a safer and more engaging drive.

- Enhanced Drivetrain Response: As an engine manufacturer, we know that a responsive powertrain feels powerful. By reducing the “slop” in the chassis, the car feels quicker and more responsive to the throttle, making the driving experience feel more dynamic.

Section 4: Implementing the Change – Upgrading Your Vehicle for Maximum Efficiency

Understanding the theory is one thing; implementing it is another. As a factory, we make upgrading to this technology accessible and straightforward. We offer a complete line of precision-machined polyurethane bushings designed as direct replacements for the original rubber components in a wide range of vehicles.

The Upgrade Process: Replacing your chassis bushings, particularly the subframe and control arm bushings, is one of the most significant handling and efficiency upgrades you can make. While it can be undertaken as a DIY project for experienced mechanics, we always recommend having it performed by a professional suspension specialist. The job requires specialized tools to safely and correctly disassemble the suspension components and press the new bushings into place.

What to Expect After the Upgrade: The moment you drive the car after the installation, the difference will be immediately apparent. The first thing you’ll notice is the elimination of the vague, rubbery feel in the steering and chassis. The car will feel tighter, more solid, and more connected to the road. As you drive, you’ll notice a newfound stability. On the highway, the car will feel less “floaty” and more controlled. During acceleration, you’ll feel the power being delivered more directly to the wheels, translating to a more responsive and engaging experience.

Over time, as you continue to drive, you will also realize the financial benefits. By eliminating the 90% of waste caused by chassis instability, you will see a measurable improvement in your fuel economy. While the exact gains depend on your driving style and vehicle, many owners report improvements of 10% or more in MPG, allowing the upgrade to pay for itself over time through fuel savings.

Conclusion

The quest for fuel efficiency often leads us to look at the most complex and expensive parts of a car. But as the factory engineers who build its foundation, we know that the greatest gains can sometimes be found in the simplest of places. The link between your engine and the road is the most critical interface for performance and efficiency.

The answer to the question, “What can save 90% of fuel waste?” is not a new type of engine or a secret fuel additive. It is a material science breakthrough that addresses the fundamental flaw in chassis design: the rubber bushing. By upgrading to high-performance polyurethane bushings, you are not just replacing a part. You are transforming your car’s very skeleton into a rigid, efficient, and stable platform. You are ensuring that the energy from your engine goes directly to powering your vehicle, not to twisting flexy pieces of rubber. This single upgrade delivers a trifecta of benefits: a significant improvement in fuel economy, a monumental leap in handling and safety, and a more enjoyable, connected, and responsive driving experience every time you get behind the wheel.